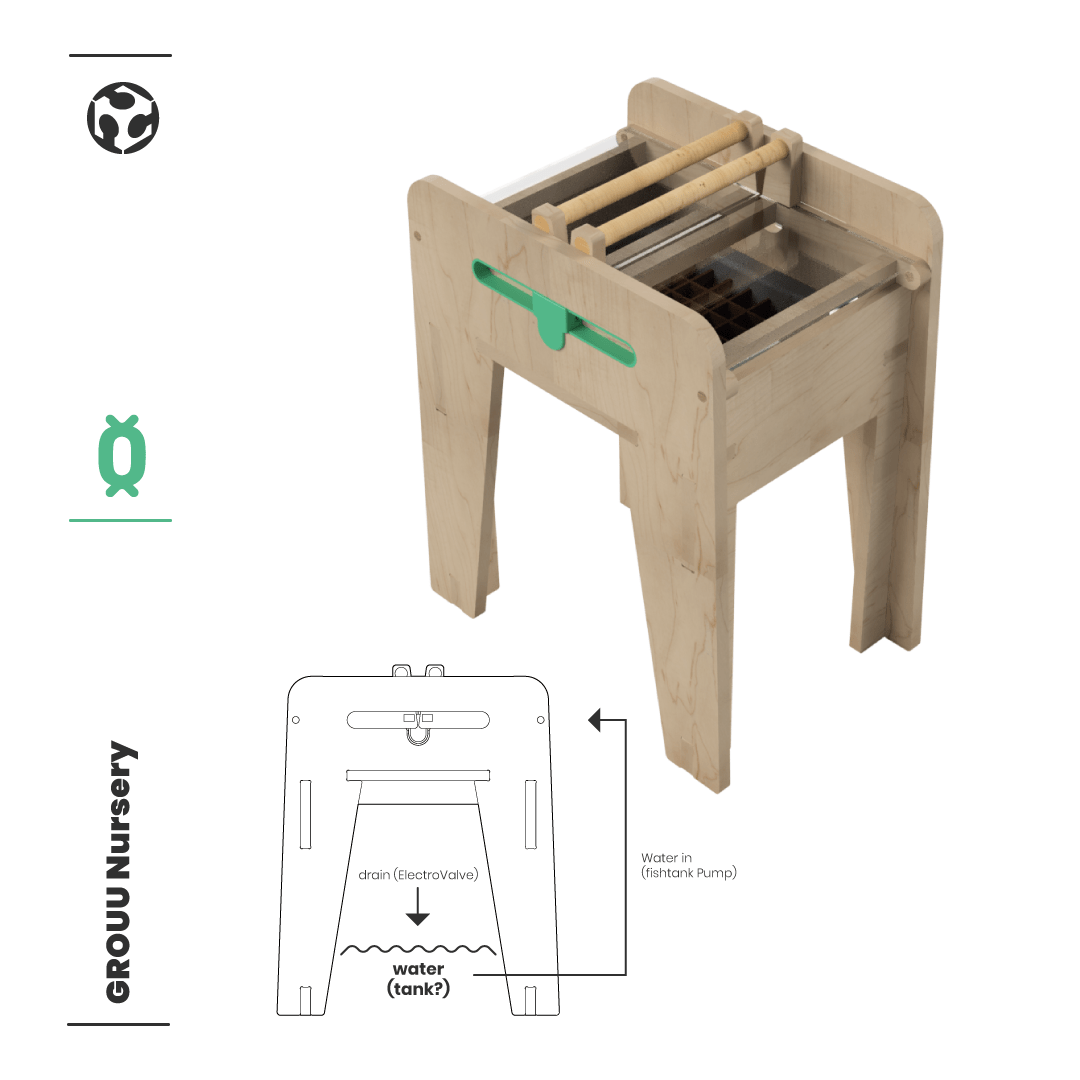

GROUU is about designing and prototyping a medium for Open Agriculture. It is a Precision Agriculture sensor network and an Irrigation and fertilization system but also a knowledge transfer system, connecting both systems and humans. >>>>>>>>>>

I'm attending Fab Academy 2018 as a continuing student. My biggest aim, besides becoming a "certified" Fab Manager, is to use this process to improve some of my personal projects. The most important one right now is GROUU. A new medium proposal for Open Agriculture, through which I’m developing my PhD research. Last year I came up with the idea of turning my first version - A fully automated greenhouse lab (grouu.cc) - into a modular and distributed solution in which sensors and actuators are independent and able to connect as nodes. In most of the assignments I will try to find and develop solutions for this GROUU iteration.

GROUU logo cc-by

GROUU logo cc-by

GROUU is an open source project aimed at creating a new medium for Open Agriculture; Inspired by Fab Academy, it will improve to best fit the idea of being able to be adopted and used by any scale or Agricultural context; That meant the shift from a fully automated Arduino based Greenhouse, to an modular Object Oriented Hardware Project.

"Git Fork" cc-by Andrejs Kirma at NOUN PROJECT

"Git Fork" cc-by Andrejs Kirma at NOUN PROJECT

I designed this tutorial to work with my students and have them use Github Classroom. Since it is a “Very Basic GIT Tutorial” I decided to include it here, under a CC License. It is a very Visual and GUI based tutorial. Follow the steps here.

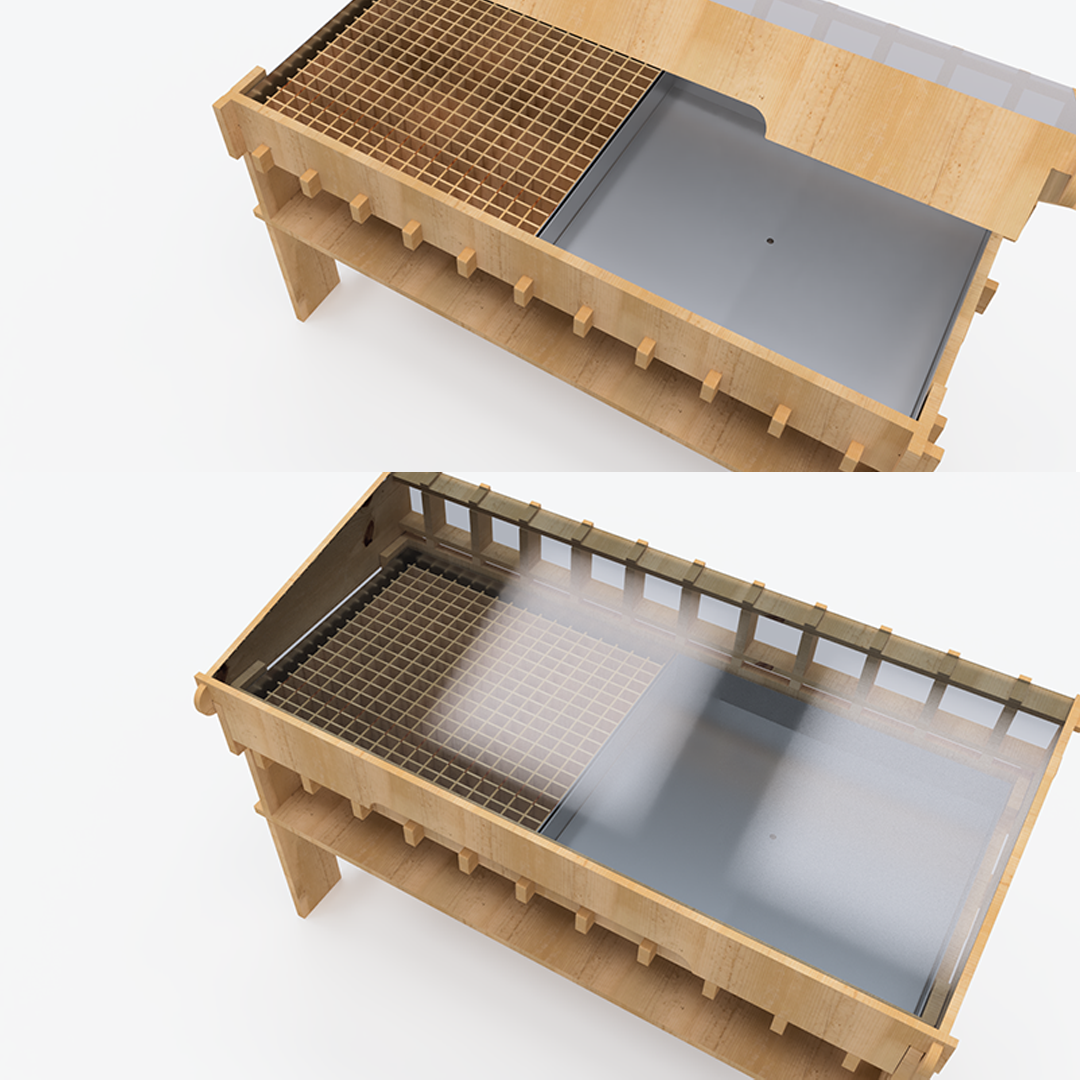

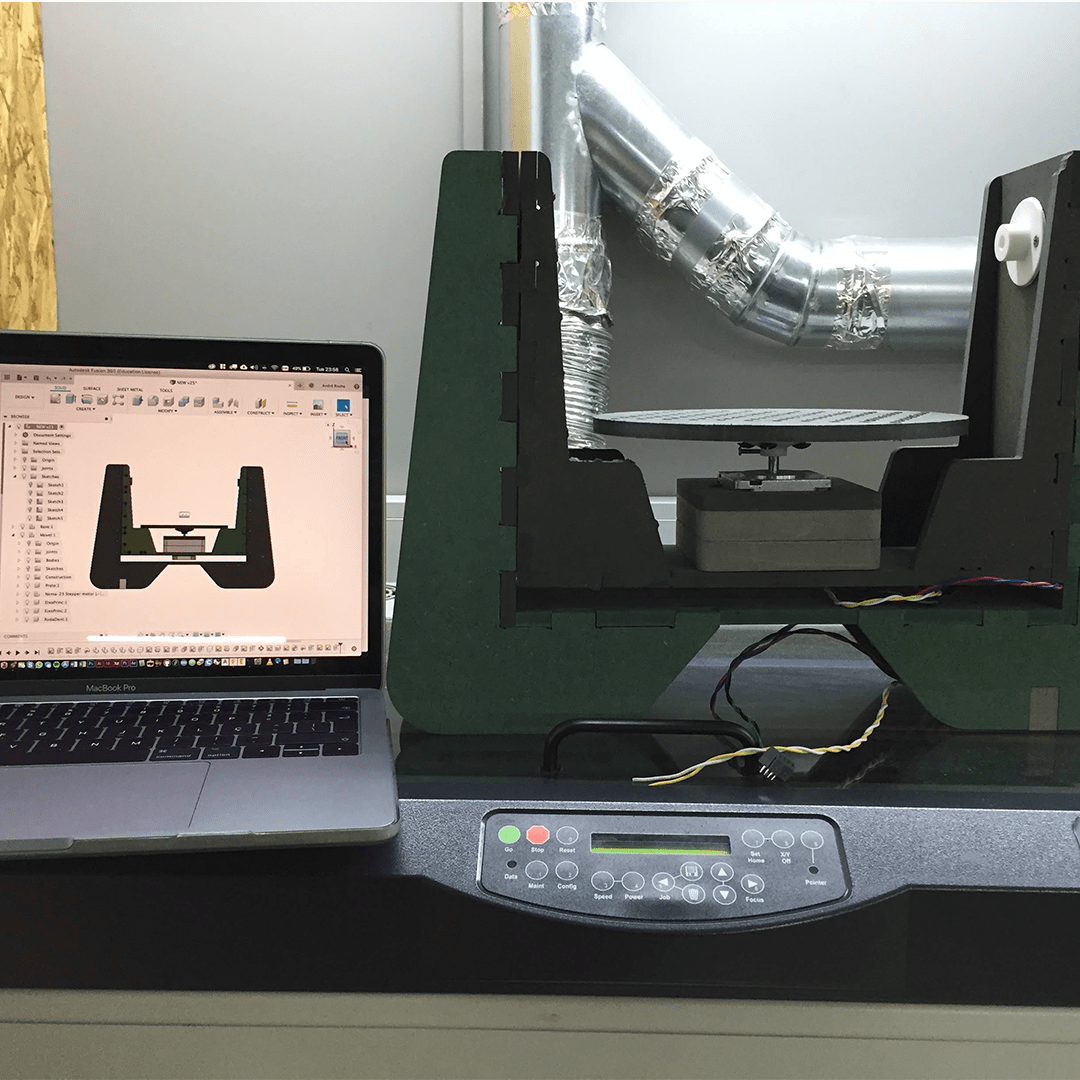

Fusion360 print screen and actual 3d print

Fusion360 print screen and actual 3d print

I had previous experience with CAD software (from AutoCAD, Alias and Rhino), Parametric software (SolidWorks and OnShape). Fusion360 looked like the next challenge to embrace:

Find out more here.

Second Jar (all-rights-reserved photo by Paulo Andrade)

Second Jar (all-rights-reserved photo by Paulo Andrade)

One of the most curious aspects of 2D cutting solid materials is the exercise of making it a 3d construction. I'm very interested in this idea of generating simple manufacturing tools trough digital fabrication. In this case I've been exploring the use of laser cutting plywood for molds.

Find out more here.

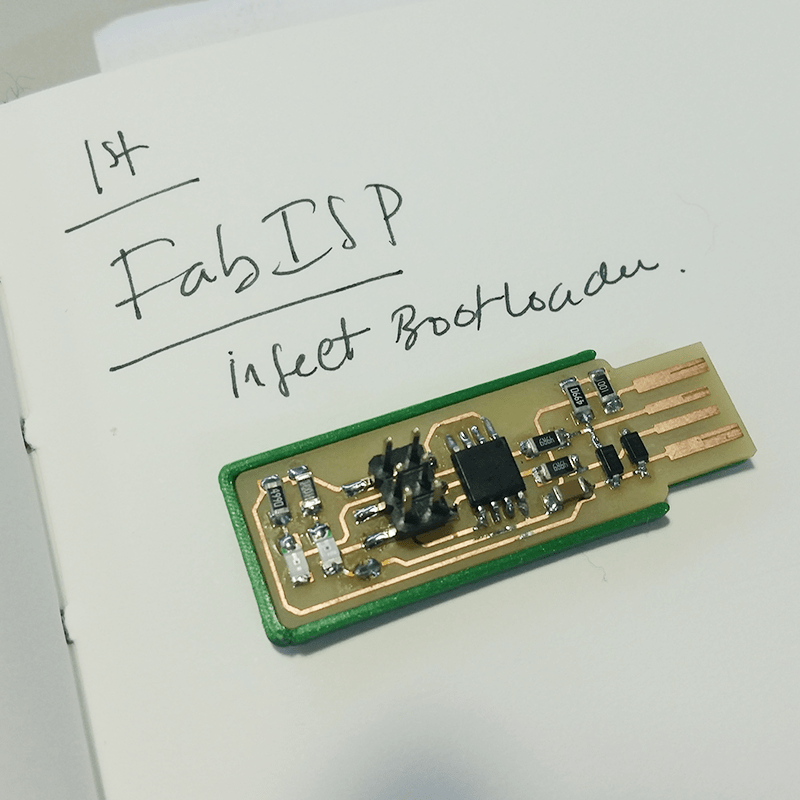

my FABISP

my FABISP

This work I already finished last year. In fact, Electronics production was a fight I took until the very end. We were producing our electronics on a semi closed/proprietary CNC called carvey

As an educational tool it carves wonders, and we managed to come up with a very simple workaround, which for simple boards like these, works very well.

More about this and next chapters here.

A Portuguese Coblestone

A Portuguese Coblestone

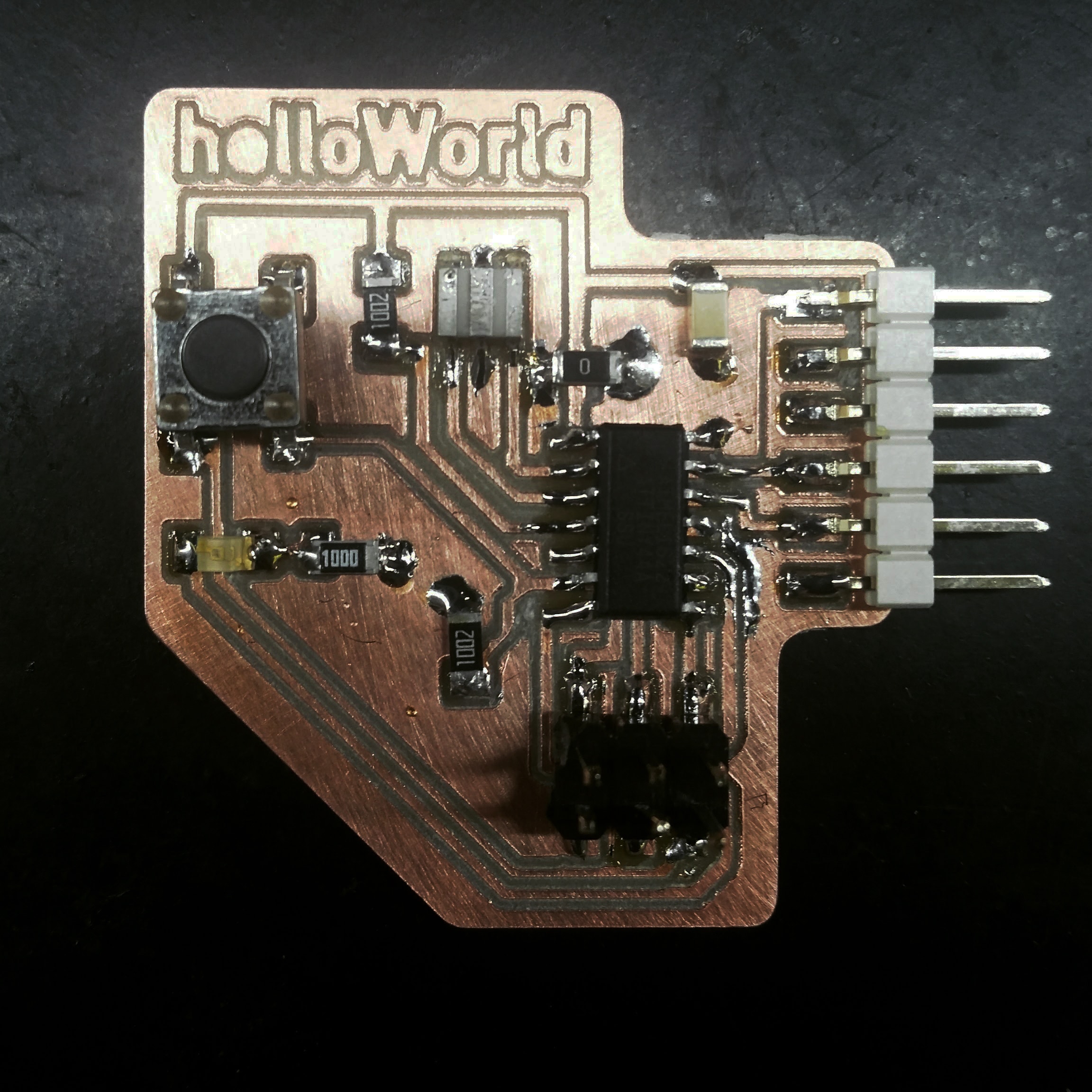

Some of the tests and a print for the final project.

Find out more here.

photo credits

photo credits

Forget sudoku or crosswords use board design! Ask your friends for schematics and design rules...

Here is my introduction to it: link.

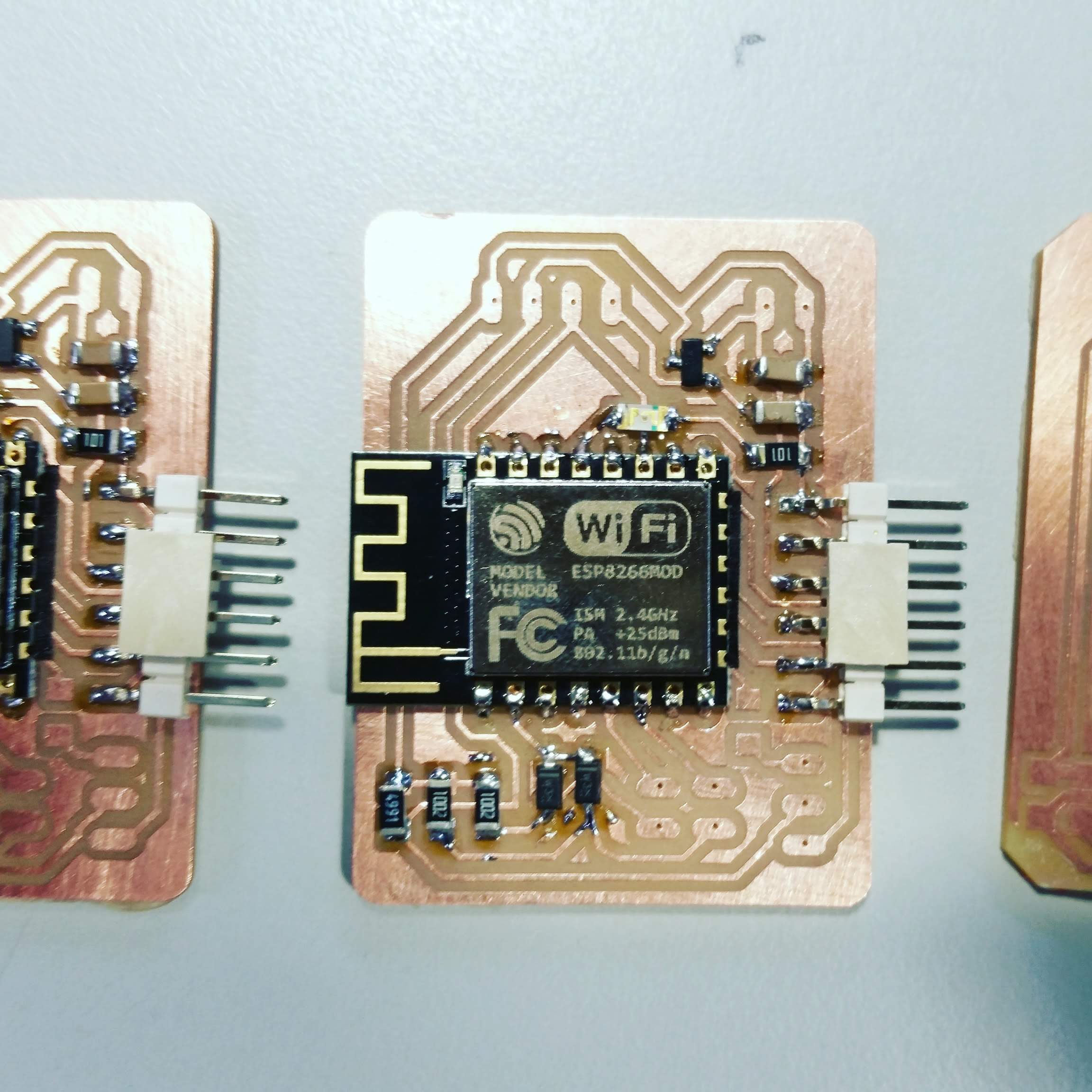

Embedded Programming photo credits

Embedded Programming photo credits

2017 sensor board code

embedded programming more here.

Scaling the Tzoumakers Iteration for Fab Academy Showcasing

Scaling the Tzoumakers Iteration for Fab Academy Showcasing

This is how I intend to scale down in order to cover a wider range of technologies with my project..

mechanical design credits

mechanical design credits

mechanical design bla bla

mechanical design programming more here.

interface and application programming credits

interface and application programming credits

I used Node-Red and the Node-Red dashboard on a server side to complete this week.

Find more here.

WildCard Week

WildCard Week

Playing with composites (Epoxi-Burlap)

Here is how I designed and fabricated the tray for my final project: !!!.

Product and Interaction Design Professor at ESELx - IPL); Technical Lead at Creative Commons Portugal; Founder at DAR - an Open Design and Culture Non-profit, where I’m also the Fab Manager at the local Fab Lab; I’m currently enrolled in the UT Austin | Portugal Digital Media PhD program where I’m researching about Open Agriculture through the design of a new medium (GROUU) which is aimed at Open Agricultural Knowledge generation and transfer. In the end of 2016 I co-founded the FarmLabs Initiative through which I also develop my Research. I started my career in 2003 designing products with a group of Artisans in southern Portugal (Alentejo). Somehow, in the middle of advertising agency work, trade fair stands, big events, design and production discovered arduino, processing, code, and a lot of things I came to admire, explore, use and research with and about. These experiences led to a balance between two parallel environments where I design, teach and research: the tech/hacking/maker/ DiY/collaborative/open source and the craft product design experiences.